| ORDER NO | ICM1705PER | MATERIAL | carbide |

| CUTTING TYPE | Shoulder mill inserts | INSERT SIZE | APKT1705 |

| INSERT TYPE | APKT | LENGTH | 0.720 |

| FINISHING COATE | PVD | THICKNESS | 0.220 |

| ISO STANDARD NO | APKT1705 PER | THRU HOLE | 0.187 |

| ANSI NO | APKT1705PER | CORNER RADIUS | 0.03 |

| CHIP BREAKER | PM | INSERT WIDTH | 0.363 |

| BRAND | iCarbide | PACK | 10PCS |

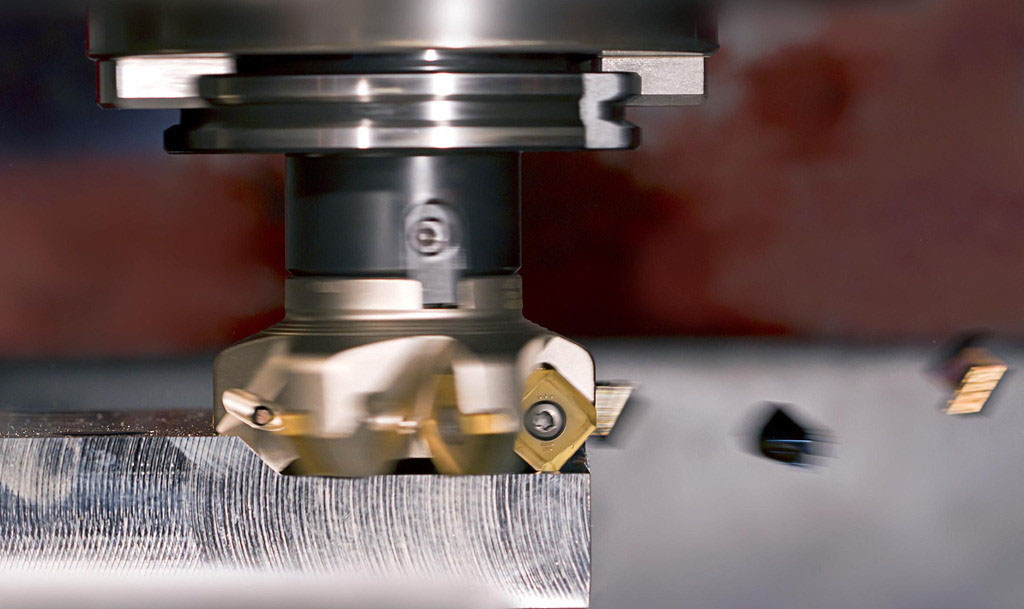

APKT1604 PDTR IG201 CARBIDE INSERT MILL INSERTS

The end face and outer circle of the face milling cutter perpendicular to the tool holder have cutting edges, which are mainly used for plane milling. The outer cutting edge is the main cutting edge, and the cutting edge on the end face plays the same role as the scraper. Compared with sleeve end mills, face milling cutters have a shorter edge.

High-speed steel face milling cutters are generally used to machine flat surfaces of medium width. The standard milling cutter diameter ranges from 2″ to 10″. The cutting efficiency and machining quality of cemented carbide face milling cutters are higher than that of high-speed steel milling cutters. Therefore, cemented carbide face milling cutters are widely used to process planes.

Cutting Grade and Condition

| K | M | P | S | N |

|---|---|---|---|---|

| Cast Iron | Stainless steel | carbon steel | Heat-resistance alloy | Nonferrous steel |

| Workpiece material | Carbide Insert Grade | V(SFPM) | fn(mm/rev) |

|---|---|---|---|

| low carbon steel soft steel | IG701 IG601 | 900(700-1200) | 0.006(0.004-0.008) |

| stainless steel | IG701 | 700(600-1000) | 0.006(0.004-0.008) |

| Tool steel | IG701 IG201 | 700(600-1000) | 0.006(0.004-0.008) |

| Cast iron | IG701 IG601 IG201 | 700(400-1000) | 0.006(0.004-0.008) |

| inconel steel | IG701 | 800(600-1000) | 0.006(0.004-0.008) |

| ALumimum ,brass ,plastic, solf steel | IG101 | 900(80--1300) | 0.008(0.004-0.008) |

Tungsten Material

It has high toughness of flexural strength and good thermal conductivity, but has a poor heat resistance and wear resistance. It is mainly used for processing cast iron and non-ferrous metals. Fine-grained YG cemented carbide (such as YG3X, YG6X), when the cobalt content is the same, its hardness and wear resistance are higher than YG3 and YG6, and its strength and toughness are slightly worse. It is suitable for processing hard cast iron and austenitic stainless steel. , Heat-resistant alloy, hard bronze, etc.

Ionbond provides thin-film coating services and operates, includes PVD, PACVD, CVD, CVA, and CVI technologies, including a broad range of DLC coatings. Please contact us for further information.

We look forward to serving you

carbide inserts carbide bit,vbmt insert,tcmt insert,dcmt insert

mill inserts,sandvik inserts,carbide insert chart,

apmt1604,APMT1135 /wnmg/tnmg insert,ccmt insert,ccmt060204,

carbide insert cnmg insertkennametal inserts,dcmt070204